AI at the Edge, Powering for Smarter Industries

Purpose-built for industrial edge AI, this compact and reliable solution is optimized for real-time vision, acoustic, and control applications — enabling intelligent performance directly on-site.

Key Products

AI Camera

All-in-one AI smart camera with C-mount lens I/F for fast, flexible inspection — plug-and-go.

- 5MP Global Shutter CMOS with C-mount lens interface for high-speed, accurate inspection.

- On-board lighting control, Wi-Fi, and GigE Ethernet for flexible deployment.

- Selectable digital I/O simplifies integration into diverse systems.

AI Computing Box (w/o Camera)

Compact design, supporting external USB industrial cameras.

- Compact edge computing unit supporting external USB-A industrial cameras.

- Includes on-board lighting control, Wi-Fi, and GigE Ethernet connectivity.

- Configurable digital I/O supports scalable machine vision integration.

Vision Hub

A highly integrated AOI platform with multiple I/O and robot arm control API.

- Integrated AOI platform supporting 2 PoE GigE cameras with robot arm control API.

- Features dual lighting control and multi-GigE connectivity for advanced automation.

- Selectable digital I/O provides flexibility for diverse production setups.

Software

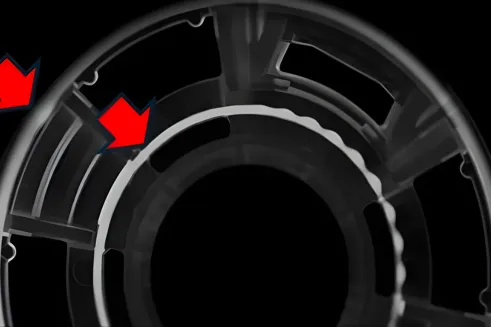

Label Printing Defect Detection

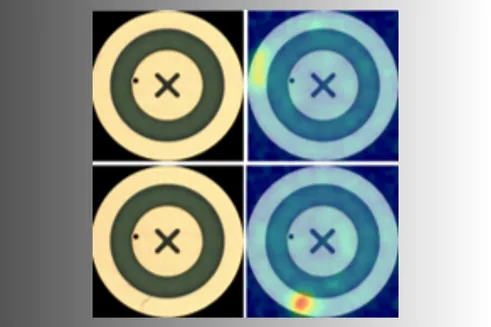

Appearance Defect Detection

Food Detection and Auto Pricing

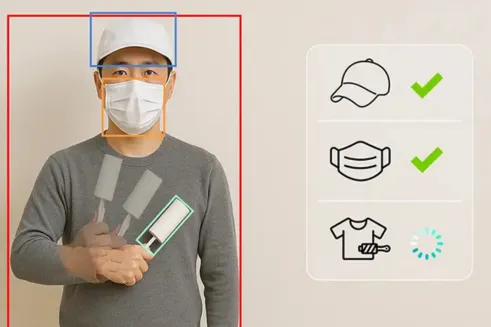

Operation Behavior Detection

Clothing, Grooming, and Hygiene Inspection

Guide and Align for Robot Arm

Glue Dispensing Quality Inspection

Automated Acoustic Noise Detection

Why Choose Primax?

X-IN-1 Sensory Fusion and Smart Manufacturing Technologies

X-IN-1 AI Sensor Fusion brings vision, audio, and interface technologies together within a single integrated design, improving performance and reducing development complexity.

Manufacturing Expertise

With 40 years in electronics manufacturing and 20 years in automation, Primax possesses deep domain knowledge and a proven track record in solving complex manufacturing challenges.

Operational Efficiency

Our automated inspection solutions reduce labor costs, eliminate human error to improve product quality, boost production efficiency and units per hour (UPH), and optimize overall cost structures through enhanced operational effectiveness

Local Support

Dedicated engineering teams and automation service centers in Taiwan and China ensure rapid, on-site support, enabling smooth implementation and maintenance for every deployment.