Life cycle assessment and product green design

Product Life Cycle

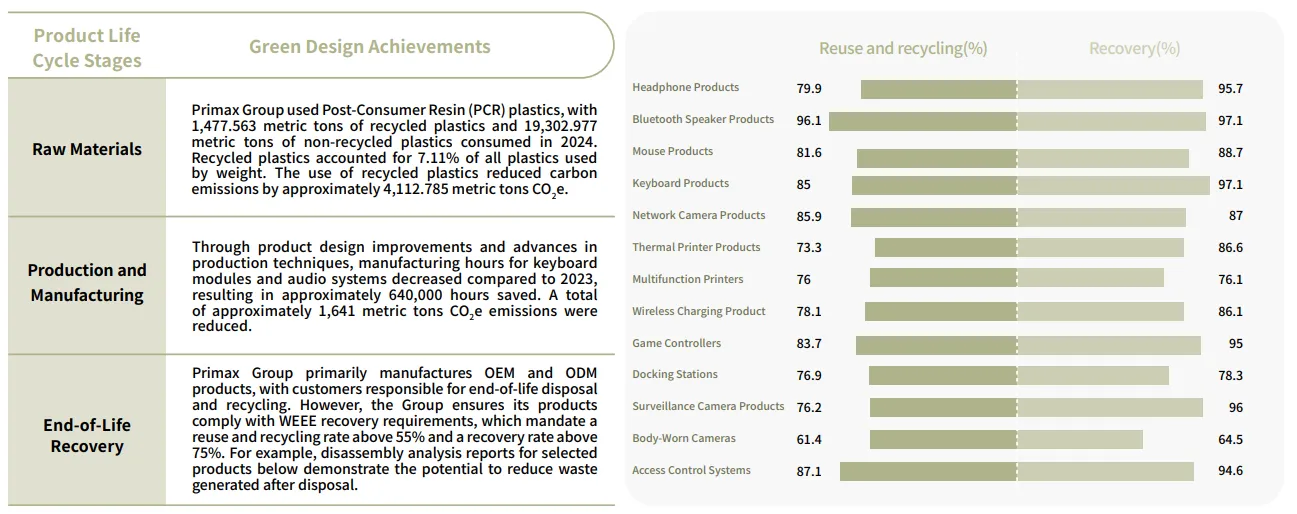

To reduce the environmental impact of its products, Primax evaluates the environmental impacts at each stage of the product life cycle in accordance with international standards ISO 14040 and ISO 14044 and incorporates green design principles. Since 2013, Primax has conducted product carbon footprint studies using the life cycle assessment methodology based on ISO 14067, selecting representative products for evaluation. Given the Group's extensive product portfolio, Primax has adopted a phased strategy to complete carbon footprint calculations across product categories.

In 2023, the Group developed a Sustainability Control Tower management system to support carbon footprint assessments and serve as the foundation for low-carbon product design. In 2024, life cycle assessments of the carbon footprint were completed for 17 major products, including mice and keyboards (wired, wireless, and gaming), network cameras, wireless charging pads, game controllers, docking stations, surveillance cameras, access control systems, multifunction printers, thermal printers, Bluetooth speakers, and headphones. The assessment covered raw material production, transportation, manufacturing, product transport, product use, and end-of-life treatment, representing approximately 51% of revenue. Going forward, Primax will further expand carbon footprint inventories and low-carbon product design efforts. Additionally, in 2025, the Group plans to develop a real-time carbon footprint reporting system for all mass-produced products to provide timely support for eco-design and low-carbon design analysis activities.

Product Life Cycle

As a company primarily engaged in contract manufacturing and assembly, Primax is committed to ensuring that every stage of the product life cycle, from upstream product design to end-of-life treatment, moves toward greener and more circular practices while meeting customer requirements. In 2024, we continued to increase the proportion of recycled plastics used in raw materials. In the production and manufacturing stage, product design improvements and advances in production techniques helped reduce labor hours. At the end-of-life phase, we adhered to WEEE compliance principles and monitored the disassembly rates of Primax products.

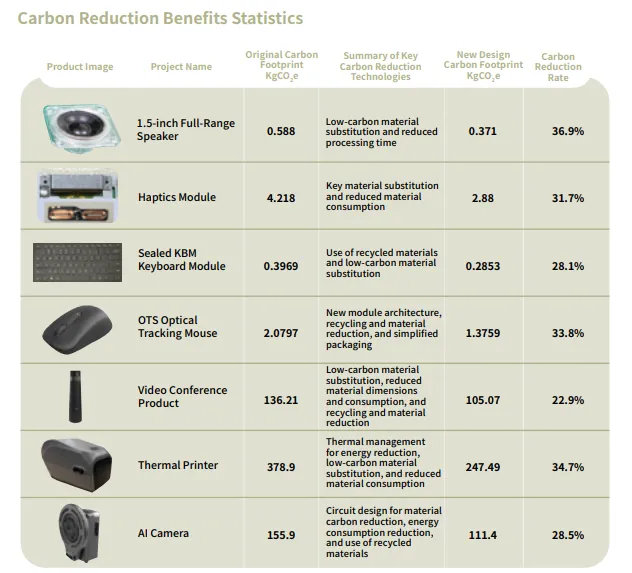

Green Product Design

Between 2023 and 2024, the Group gradually established foundational capabilities in eco-design and low-carbon design and developed a product carbon footprint information system to compile baseline data for product carbon footprints. In 2024, Primax officially launched low-carbon design projects for major products and set a design target to reduce the carbon footprint of these products by more than 20%. This target has also been incorporated into the performance management and incentive mechanisms for R&D leadership.

Low-Carbon Design Projects

In 2024, resources invested in green product design totaled NT$69.46 million, including investments in personnel resources, project expenses, dedicated equipment, carbon footprint management system development, and training.

Chemical and hazardous substance management

Primax Group strictly complies with the chemical safety regulations applicable in various countries and customers' requirements on prohibited and restricted substances. By controlling the stages including design, procurement, manufacturing and output comprehensively, it expects to move toward the goal of zero health and safety hazards and zero environmental pollution. Primax never incurred any chemical spills or other incidents in 2024

Focus on the chemical laws and regulations development trend

Primax Group operates production sites across multiple regions. Accordingly, we closely monitor chemical-related regulations in each location, including but not limited to the European Union Restriction of Hazardous Substances in Electrical and Electronic Equipment Directive (RoHS), Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), Persistent Organic Pollutants Regulation (POP), the Environmental Protection Agency Toxic Substances Control Act (TSCA), California Proposition 65, Limits for Volatile Organic Compounds Content in Cleaning Agents, Limits for Volatile Organic Compounds Content in Adhesives, and other international standards and Chinese national regulations.

In line with applicable regional regulations and customer requirements, Primax Group has established the Primax Green Product Chemical Substance Restriction Specification. Through coordinated oversight by multiple departments, including Environmental Health and Safety, Production, Green Product, and Product R&D, the Group manages the use of chemicals at every stage of the manufacturing process.

Primax Group's Green Product Management Platform

To implement effective source control, Primax utilizes a Product Data Management (PDM) system as its core platform, integrated GP Portal®, SAP®, and other information systems to build a comprehensive management infrastructure.

Full Material Declaration (FMD)

Primax Group integrates its PDM®, GP Portal®, and SAP® management systems to identify the material composition of all components.

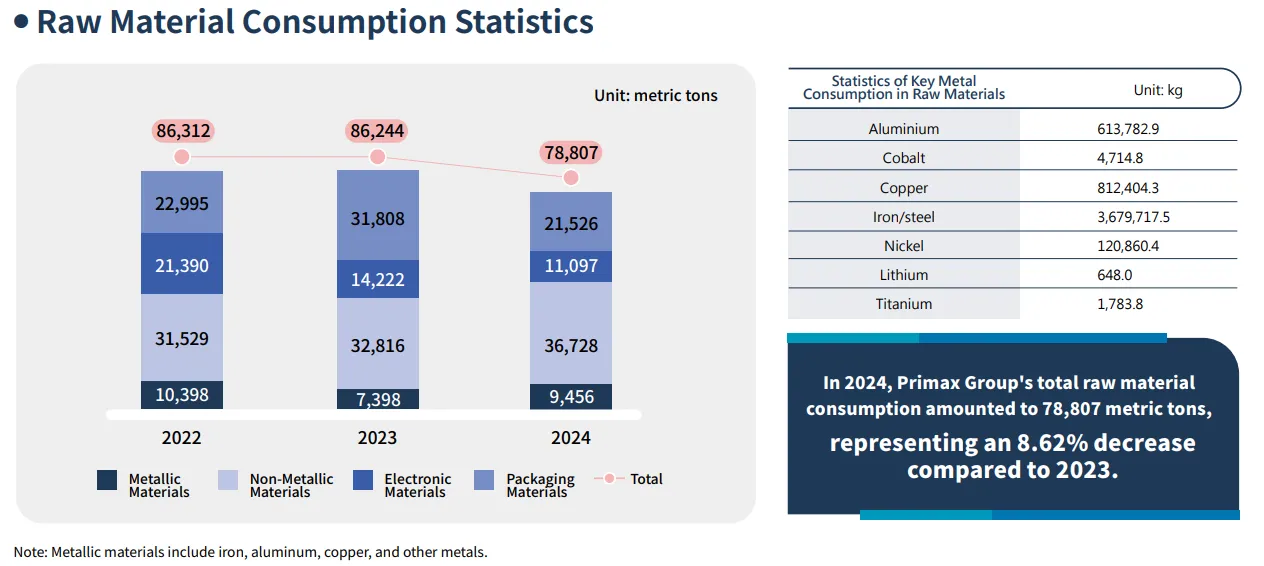

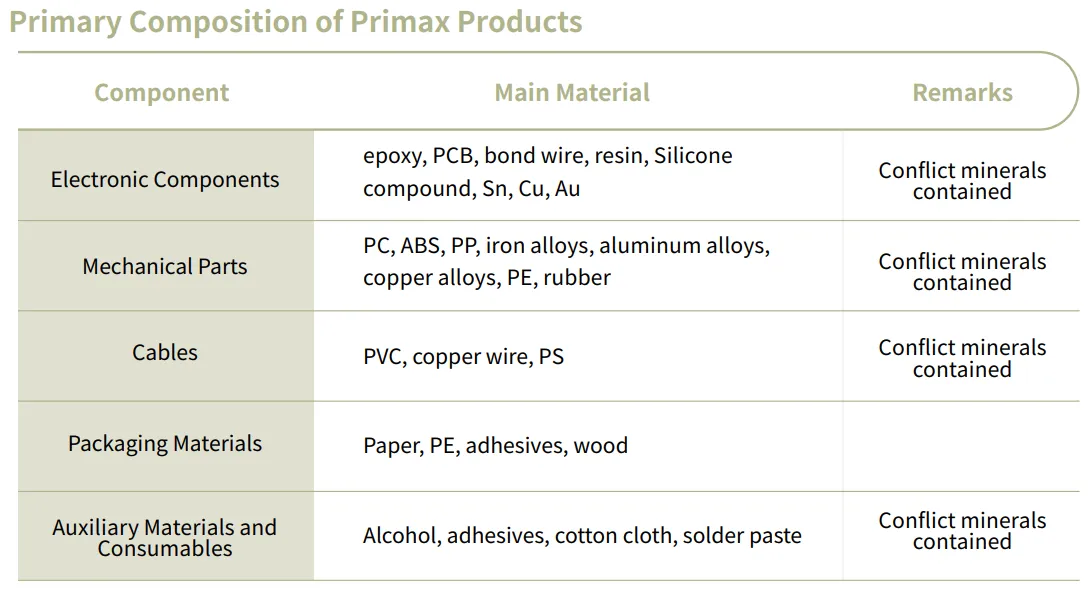

Raw material consumption statistics

In 2024, Primax Group's total raw material consumption amounted to 78,807 metric tons, representing an 8.62% decrease compared to 2023.